First time on the job site: Intern describes her drywalling experience

Hi, my name is Madison Winter, a Construction Management Student at the University of Minnesota. I just completed my summer internship at Mavid Construction, and I’m sharing about my first time working on a commercial construction site.

As a previous Architecture student, I’ve unraveled all the steps of completing a project, from pre-design to substantial completion. The only thing I’ve never been familiar with was being able to perform the construction myself, so I was excited to spend an extended period of time in the field with seasoned professionals.

My first job site visit was to a Green Bay hospital currently undergoing major renovations to its 3rd-floor. This 20,000-square-foot project is transforming the previous cafeteria into a new and upgraded NICU to accommodate more patients. Mavid Construction is providing flooring and wall coverings for the estimated 50 new rooms that include patient care, offices, and nursing stations.

I specifically worked with the drywall team and got to see firsthand the assembly of an interior wall. This installation process included:

- Metal studs

- Insulation

- Drywall

- Mudding and Taping

- Paint

I was first put on the finishing crew to help assist with the covering and patching of new and old drywall. We consistently worked on six-to-eight patient rooms and bathrooms. Typically joists, seams, and corner beads receive two coats of joint compound, however, light plays a big factor in the appearance of a wall. When light shines through a window, from certain angles, you’re able to see hollow or dented surfaces. This was very important, especially where the corners defined the room. If there wasn’t natural light, oftentimes finishers used their own light sources to exploit these deficiencies.

You then have to cover the screws that hold the drywall to the metal studs. This takes three coats. Patching outlets or holes need to be covered at least twice. I was lucky enough to be mentored by Mike Morgan and Doua Vang who taught me many techniques when using a finishing knife. It may seem as if you can wipe everything flat, but it is all about the gradation of the mud to make the wall appear flat. This requires certain angles of the knife and thickness of mud. As a beginner, it was a messy job.

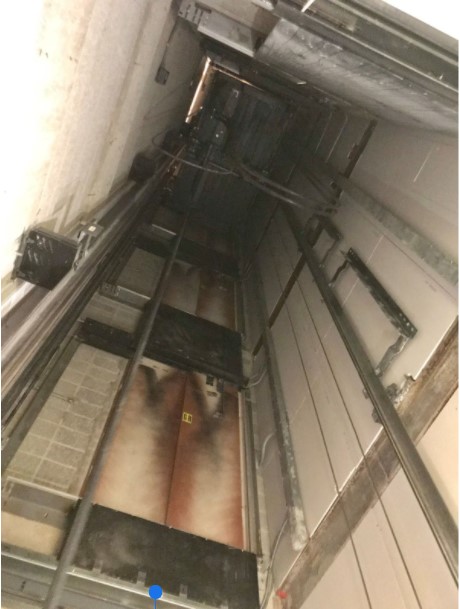

I was then introduced to hanging drywall, also known as “rocking.” When rocking, you are paired with a partner to help you. I am lucky to say the first time I ever hung drywall was in the shaft of an elevator. In order to do this, an elevator company had to rig and build a platform on the top of the elevators for us to safely ride on. An employee operated the elevator during the entire process to keep the team safe. We measured and constructed our metal frames and then screwed drywall on one side. The primary use of the drywall was for the protection of the elevators during the remodel and installation of new elevator doors leading to the third floor, so insulation and rocking on both sides of the stud were not necessary. My partner, Chad Olson, turned my struggle of barely being able to screw in drywall, into a mediocre rocking partner to keep up and assist him.

Even though my work at the site eventually came to an end, the crew is still trucking along to finish the hospital. After the drywallers have completed their scope of work, paint, flooring, and finishes will begin to bring the hospital to life. When I come back to visit, I will be proud to say I built some of those walls with my own hands, and that is the most rewarding thing about construction.

To learn more about Madison’s experience, watch her video interview recapping her overall summer internship at Mavid Construction below.